WINDOWS

Sliding Windows

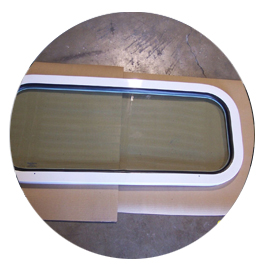

Sliding windows 3000 series :

Siding windows are commonly used in the commercial and recreational industry. They are ideal for tour vessels and inland ferries in salon, bulkhead, and wheelhouse applications. These windows provide maximum ventilation when open,and become weather tight when closed. Heavy duty, self locking, lock systems provide for a strong secure close in the locked position. Specially located flip locks mounted on the inside still secures the sliders in the open position. These windows are also available with optional screens and interior finish rings. Also see screens and trim rings in our fabrication guide for additional information.

Our two track Vertical sliding windows have the same characteristics and options as our Horizontal sliding windows. They are commonly found in doors or in wheel-house applications.

Windows Windshields & Doors

Ocean Dynamics USA will manufacture products designed to OEM and custom specifications for individual and production projects.

Manufacturing Facility

10,000 sq. feet, main line plant, Miami Florida.

Glazing for 3000 series

The 3000 series windows are designed for glazing up to ¼’’ thick. The standard type of glass used for this application is « tempered glass » As an additional safety option, this glass is available in « tempered laminated feature. Another option is Acrylic (a high grade acrylic). Regular Laminated safety glass is not available in sliding windows. With these options there ar many available tints other than clear which include, Green (solex), Bronze, Gray , or dark Gray . For additional information regarding these options, please refer to Glass tints and option chart .

Sliding windows also require additional components which are a part of the glazing system. These components include our V-473 track glide, F-485 Wool pile, H-714 Knob/glass pull, A -400 Lock systel, H-722 Grommet, and the V-480 Foam tape.

For additional information regarding these components , please refer to Accessory page.

Hinged Windows

2000 series

Hinged and Opening insert windows gives clear visibility and flow-through ventilation which enhances the application of this style window. The opening hinge locks into the frame, yet allowing simple removal of vents for cleaning. Our watertight seals are also replaced when frayed or worn out. The 2000 series windows come standard with heavy duty adjusting arms. Dual adjuster arms lock and secure the vent when open or closed. When closed these opening windows are watertight. Dual rotary locking rings firmly seat the vent to the frame forming a water tight seat when closed . These windows are mainly used for deck houses, bridges, and staterooms.

Radiused windows : 1000 & 2000 series

The standard size radius is 3’’ in most of our standard and medium duty series windows. In applications where trim rigs are requested, the radius used is 3/4’’ . The openning or hinged style windows (2000 series) uses an external hinge which is welded to the frame and the opening vent.This external hinge allows the vent to open to an angle of 180 degrees. Heavy duty adjuster arms allow for large opening vents for increased air flow. However, opening vents should not exceed 26’’ in height or 48’’ in width to prevent excessive fatigue on the adjuster arms.

Glazing for 1000 & 2000 series

The 1000 and 2000 series windows are designed for glazing up to ½’’ thick. However the most common thickness of glass in standard windows is 3/16’’ – ¼’’. For larger ocean going vessels 3/8’’ or thicker is appropriate. The standard type of glass used in these applications is « tempered glass ». As an additional safety option, this glass is available in « tempered laminated glass) which offers the strength of tempered glass combined with the safety laminated feature. Other options include regular Laminated safety glass ( plate glass with a laminate filler), or acrylite ( a high grade acrylic). With these options there are many available tints other than clean which include, Green (solexà , Bronze, Or dark ray. For additional information regarding these options, please refer to Glazing in our fabrication guide.

These windows are available in standard, medium, heavy duty,

Fixed windows

1000 series :

Fixed windows are used in many types of applications ranging from the small/midsize recreational and offshore workboats, to the heavy commercial and military vessels. These windows are available in standard , medium, heavy duty, and can have either mitered or radius corners. The 1000 series fixed windows are waterproof and meet CG/ISO12216 testing specifications.

The radius or mitered corner welded frame window, insures for a strong and water-proof fixed window, designed to withstand rough sea going conditions. Glazing from 1/8’’ to ¼’’ in most common applications and 3/8’’ to ½’’ in more demanding marine environments, insure a very high breaking strength . The seamless welded frames are designed for exterior mounting ( outside-in) with screw-through holes provided in the 1’’ flange. Matching interior trim-rings are available in many different sizes. ( customer should specify bulk-head limitations to insure correct width and/or leg size of rim-ring). For the heavy duty line of windows , a more modest , self-finishing, bolt on trim ring comes standard as a part of the basic window structure.

Glazing for 1000 & 2000 series :

The 1000 and 2000 series windows are designed for glazing up to ½’’ thick. However the most common thickness of glass in standard windows is 3/16’’ – ¼’’. For larger ocean going vessels 3/8’’ or thicker is appropriate. The standard type of glass used in these applications is « tempered glass ». As an additional safety option, this glass is available in « tempered laminated glass) which offers the strength of tempered glass combined with the safety laminated feature. Other options include regular laminated safety glass ( plate glass with a laminate filler), or acrylite ( a high grade acrylic). With these options there are many available tints other than clear which include, Green (selexà, Bronze, Gray ,Or dark Gray. For additional information regarding these options, please refer to Glazing in our fabrication guide.

Screens (optional in 2 Track style) :

A screen be mounted with a fixed glass in the outside track of the 2 track window. The screen may be removed for cleaning or screen fabric replacement.

FLANGELESS FRAMES (optional) :

For recess mounting windows in a thick bulkhead, the frames may be provided without the 1’’ mounting flange. Screws are then driven laterally or T-bolt are inserted through the frame and bulkhead from inside the track channels.

Installation :

Windows : All insert type flush mounted windows are designed to be installed on flat to surfaces only. The mounting holes are drilled and counter – sunk into the flange prior to the finishing process. The holes are commonly sized for #8 screws and are spaced anywhere from 4’’-8’’ apart. Unlike bolt or clamp-on windows, trim ring mounting holes are drilled off-point from the holes in the window frames, allowing the finishing screws to be driven from both sides of the cabin wall. These holes are also commonly sized for #8 screws. If the requested application calls for through-bolt type windows, the holes are drilled on-point (in-line) with the holes of the window frame.

Curved or arced windows : In some applications, windows are designed to conform with the contour or arc in a bulk-head, these contours vary from slight to moderate which may require stretch-forming the extrusion to conform with the corresponding contour. Depending on the type of window and contour, custom tooling and dies may be required.